21. Let's Travel!

Time to Load and Go! Months of browsing ads on Facebook Marketplace finally paid off with the purchase of a great trailer. It was one of few used trailers having a clean title.

20. Launch!

At last it is time to launch these vessels and see how they perform. The first will be a family-only “soft” launch event. Later I’ll schedule a public “launch party”.

19. Outfitting

With four coats of varnish applied I’m moving on to outfitting the kayaks. It is time to install the hatches, seats and foot rests.

18. Varnish, Sand, Varnish

This process is exciting! It is so rewarding to see the beauty of the wood grain revealed by this quality wood finish.

17. First Splash!

I test floated one of the kayaks in my neighbor’s pool. It felt so good to sit down in that boat…it seemed quite stable.

16. Paddles and Back Rests

Paddles and seat back rests are accessories commonly purchased as commercial products to complete one’s kayak. I decided to construct my own.

15. A Timelapse and Cockpit Combing

I can build three kayaks in 2-1/2 minutes! Well, maybe if you watch my 2 minute and 20 second timelapse video.

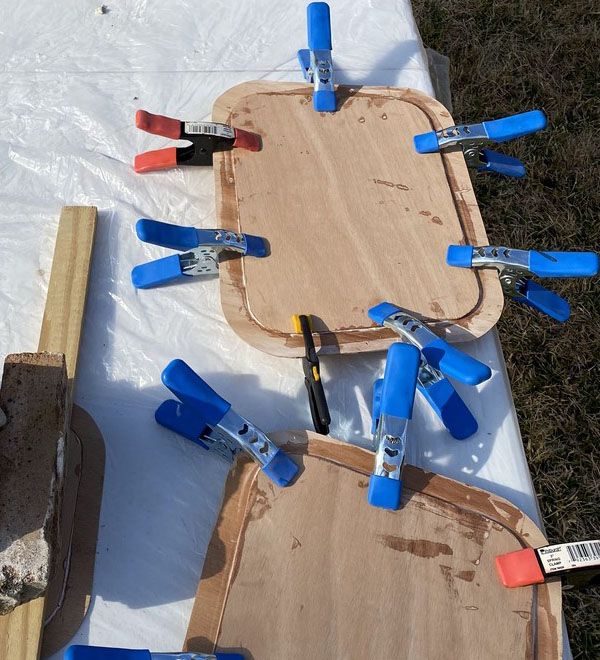

14. Cockpit Time!

There it is… This “oval of clamps” photo is proof I’m on the back end of the curve. The kayaks really look like kayaks now.

13. The Sandstorm

Exterior work is far easier than interior, but there is still an awful lot of sanding… Ensuring the plywood and joints are smooth before proceeding with epoxy and fiberglass sheathing is laborious

12. Joining Deck to Hull

We’re really building boats! Work was completed on the interior of decks and hulls, allowing the pairs to be bonded together - forever taking the shape of kayaks.

11. Mardi Gras Mambo

Watch a parade, sand the kayaks, watch another parade, mix and apply some epoxy, catch a third parade, more sanding… sleep.

10. You Can't Hurry Love

No, you can’t hurry love when you’re building three kayaks from plans.

9. Chill Out!

Winter has arrived in south Louisiana as evidenced by this icicle dangling from a hose bib. The cool weather halts epoxy work as it won’t cure.

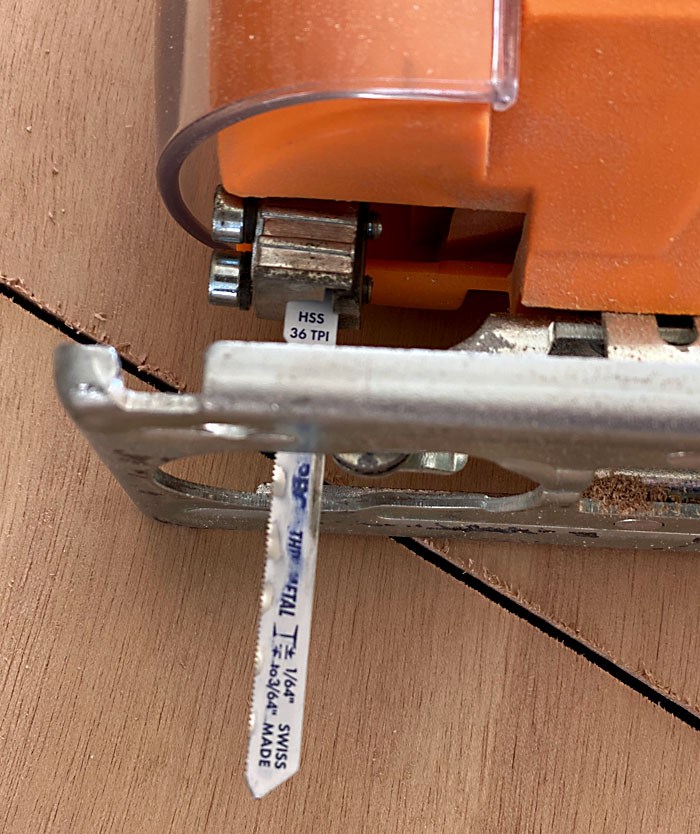

8. Cutting Hatches

Time to cut the hatches! I was nervous about this step, but I took my time and it was easy.

7. Project Resumes

Divine providence has provided an opportunity to resume building kayaks.

6. Rain and Horses

The “big wait” is what much of 2021 turned into. Spring 2021 brought lots of rain to south Louisiana.

5. Panels Cut

It is a relief… to be finished with cutting out the panels. I anticipated it would be challenging but it took much longer than I expected.

4. Begin!

Measure twice…cut once! We begin the careful process of cutting the components for the kayaks from plywood sheets.

3. Setting Up Shop

Making room to assemble these boats seems nearly as challenging as building them.

2. Sourcing Materials

It’s time to start the project by ordering plans and materials! I narrowed down my choices but still agonized over the final decisions.

1. The Dream

I’ve been dreaming of owning a fast, light kayak for years…decades really. I got the bug shortly after moving to Sarasota on Florida’s Gulf coast in 2000.

0. Links to Other Builds

I’m not the only builder who has documented their stitch-n-glue kayak project.